For a few weekends now I have been 'dry-running' the servo electronics that are going to replace stepper motors on the cnc mill. So far the servos are working in closed loop, I can control the VFD forward/reverse and set the RPM, I can read in a spindle-encoder to verify the RPM and also do rigid tapping. The coolant relay works. There's a jogwheel that can be used for jogging the machine or adjusting spindle/feed-override.

Still on the to-do list are limit switches, home switches and homing, improvements to the E-stop loop, and linking up some pendant buttons.

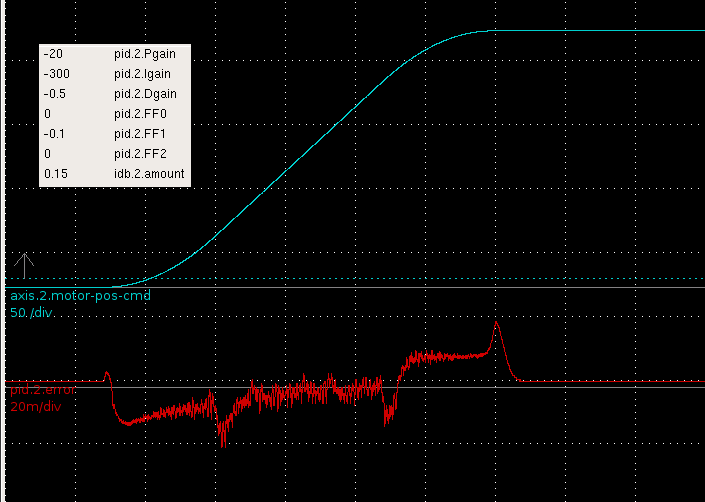

I did a little PID-tuning today with one servo motor just sitting on the bench - no load. The final PID parameters when the motor is hooked up to the machine are probably going to be different from these, but at least I got some experience with tuning. I'm using the Mesa m5i20 to read encoder counts and output PWM to pico-systems servo amplifiers. The servos have 1000-line encoders so I get 4000 counts per revolution. The ballscrews are 2.5mm/revolution, so one encoder count corresponds to 0.000625 mm.

When tuning I did a 200 mm long G0 (rapid) move which allowed the motors to get up to max speed which was set to 6000 mm/min. With the servo directly coupled to the 2.5mm/rev screw that corresponds to 2400 RPM. When coasting at 6 m/min the DAC output was at around 8.7, so this is about as fast as the motors will go (unloaded). In the machine I might not be able to reach 6 m/min. Below some hal-scope screenshots that show how the pid-error changes when tuning the PID parameters.

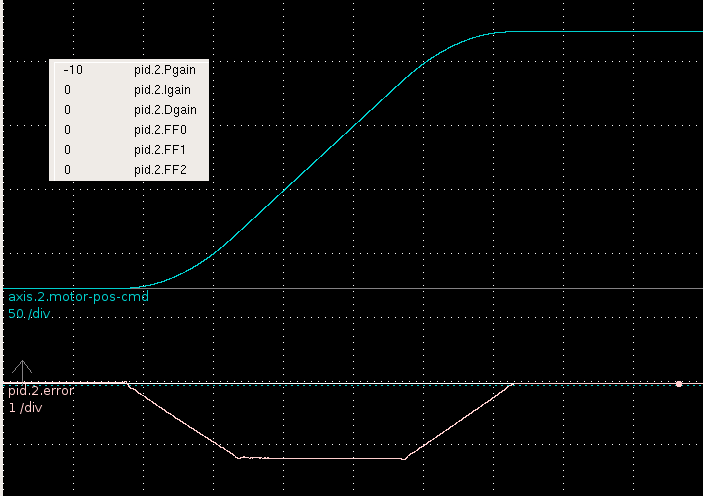

First I tried only Pgain. The error clearly shows the three phases of the EMC2 trapezoidal trajectory generator. There's an initial acceleration phase during which the error grows, then the cruise phase where it stays constant, and then a deceleration phase at the end. The following error is big, more than 1mm. Obviously I've set FERROR and MIN_FERROR quite high in my ini file so EMC2 doesn't respond with a following error and stop all motion.

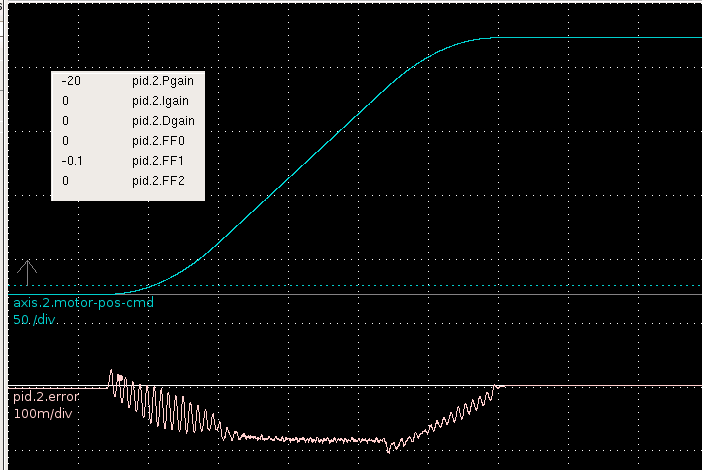

Next I tried increasing the 1st order feed-forward, or FF1, parameter. That worked well, and the error is cut more than ten fold!

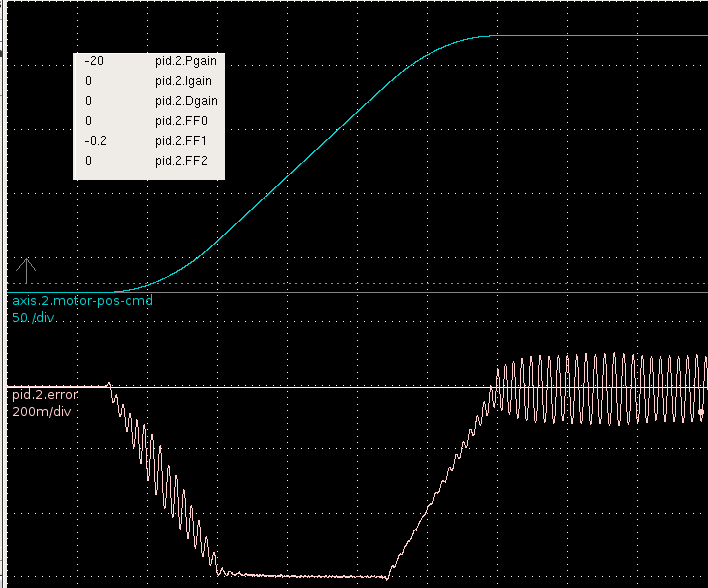

So FF1 is a good thing? More of that then! Well not quite. Here I've increased FF1 to 0.2 and get sustained oscillations at the end of the move.

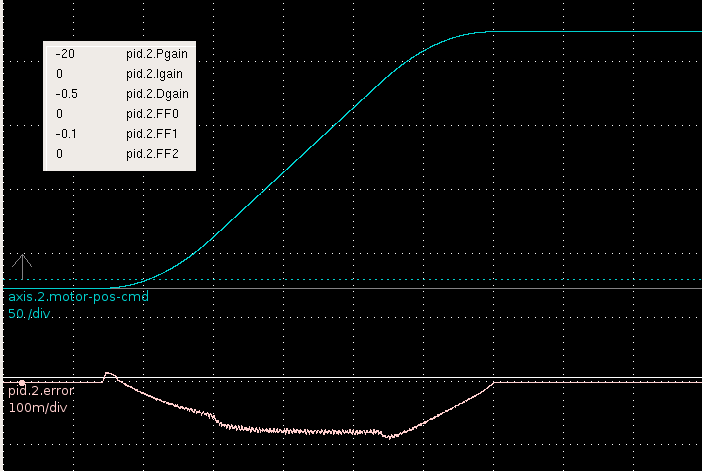

It's back to FF1=0.1 and a little D-term to the rescue for damping out the oscillations. Seems to work quite well.

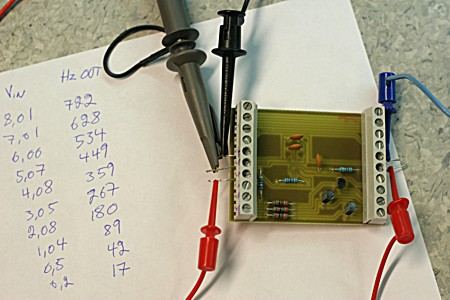

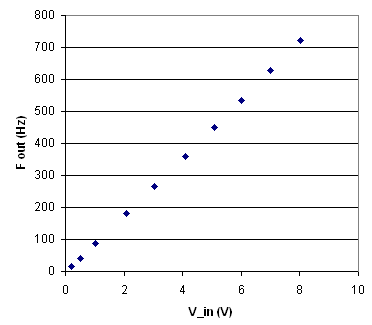

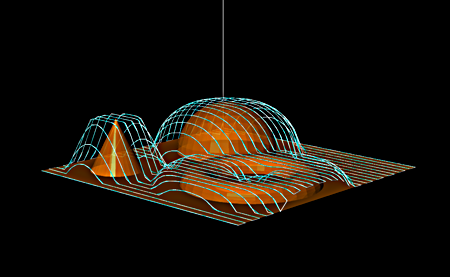

Finally I ramped up the Igain. That helps to reduce the cruise-phase error a lot, but there still remains some following error during the accel/decel phases. There are spikes at the beginning and end of the accel/decel phases which I should try to get rid of. I guess some spikes will always remain since EMC2's trajectory planner outputs a trajectory which is only once differentiable (i.e. the velocity plot has 'sharp corners', and the acceleration plot has discontinuities, see pic here). I'm also using the inverse-deadband component to compensate for the open-loop response of the motors (see next post).

The maximum error is around 0.02 mm, or ca 32 encoder counts. I'm hoping the motors will perform at least as good as this when in the machine!