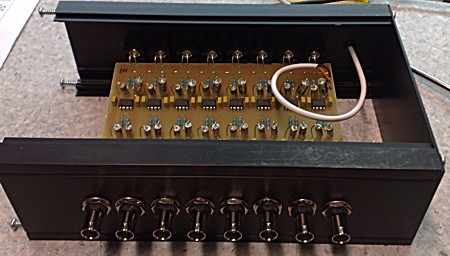

As a first serious test-run for our now servo-controlled cnc mill we decided to make an IOM bulb out of steel. It ends up a bit bigger in volume when made out of steel compared to lead, but the difference isn't huge. Making it with a cnc mill allows designing almost any reasonable 3D shape you can imagine.

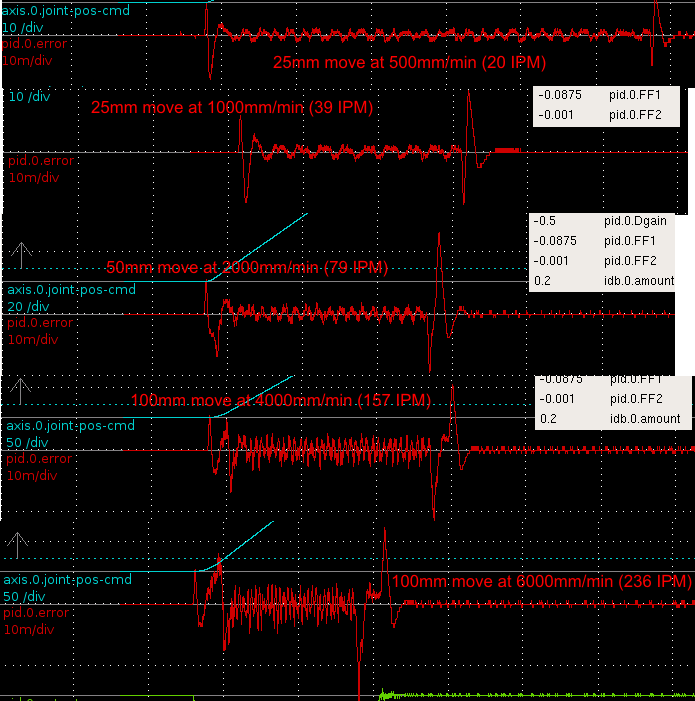

The mill worked fine during the whole run, about 3 hours of rough-cutting and 1.5 hours of finish cutting, but there was a slight operator error in the setup which means this bulb will likely not sail. The following error stayed low throughout the run, and the servos weren't even hot to the touch after the workout.

We used adaptive roughing paths and then a simple parallel finish path. Both operations are cut with an 8 mm flat cutter. The adaptive paths did seem to work, and on this size machine they are really handy since a slight over-cut will likely stall the spindle motor (1.5 kW and 5000 rpm, small by big-iron cnc-standards).

0:00 rough cutting begins. The stock is a 45 mm diameter steel bar, face-milled down on the sides so it can be clamped to the machine vises. Note the cutting feedrate which is 500mm/min and 'high-feed' in the (x,y)-plane when the tool is positioned for the next cut. When the tool lifts up to the clearance plane it does normal G0 (rapid) moves.

1:34 more rough cutting on the other end of the bulb.

1:58 still pics of the rough-pass almost ready

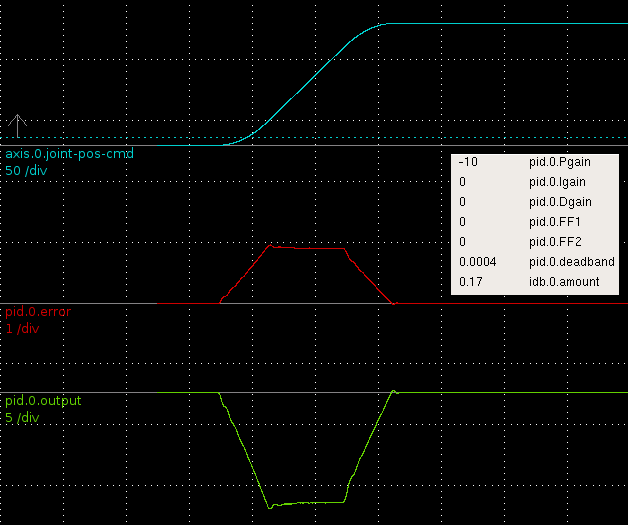

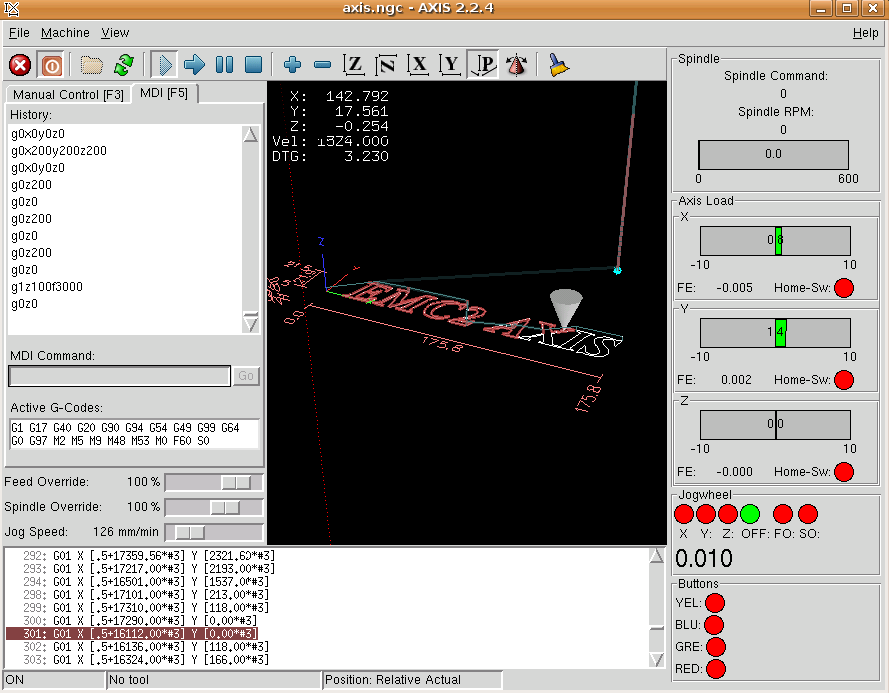

2:15 view of emc2 while cutting. Note pyVCP bar widgets showing commanded PWM to servo motors.

4:29 beginning of parallel finish cut. programmed feed 1500 mm/min which is attained briefly in the middle of the move.

5:00 more finish cutting, about 2/3 done.

5:50 another view of emc2 and the pyVCP panel. Note Y and Z motors working to position the tool. The following error for each axis is also shown.

6:15 still pictures of the finished bulb (well, one half of it anyway). Note at the front of the bulb we tried to run the program at 150% of programmed feedrate, but that didn't work at all and resulted in a poor surface finish. We did try to slow down also from 100% but that didn't improve the surface much.

Google video doesn't really do justice to the nice 640x480 video and 5 Mpix still-photos that come out of the N95, so if you've bothered to read this far, here's the original 100 Mb mp4 (I hope I don't exceed my bandwidth limit).