The new high-torque winch servo is 44x22mm instead of the standard 40x20mm, so we made a new radio-plate for it today. The new plate has a bigger cut-out for the new servo, and is slightly wider. The boat will sail again next weekend so we will hear how the new servo works then.

Category: Model Yachting

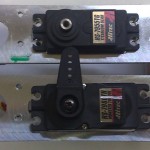

Monster torque servos

Gone is the HiTec light-blue box, and replaced with a clear one. These servos, which HiTec calls "monster torque" 🙂 are designed for either 6.0V or a LiPo pack at 7.4V. They are about 10% bigger than the standard 20x40 mm footprint, and produce 36 kg*cm (6.0V) or 44 kg*cm (7.4V) of torque. To be tried as a winch servo in the prototype PIKANTO.

2010 Finnish MicroMagic Open

22 skippers with guests from RUS, SWE, and NED, in addition to FIN skippers came to this two-day event in Espoo. For me it was a non-event since I don't own the smaller MicroMagic rigs that were required during the first day with steady 7-8m/s and up to 11-12m/s of wind in the gusts.

At times you hear voices out there who mutter that the IOM sort of "fails" as a one-design because there isn't a minimum fin thickness, and the minimum weight is so low it is really difficult to DIY build a competitive boat on your own kitchen table. In contrast, the MicroMagic seems to do a reasonably good job of "pure one-design" with the hull and appendages, although people do play around with combinations of MkI and MkII fins and rudders.

But compared to the IOM, the MicroMagic rigs are a completely wild jungle! Although the biggest no1 (or should we call it "A"?) rig is limited to the stock size sails which come with the kit, there are little or no limitations on the smaller rigs. When there is this much freedom, people are bound to explore the design envelope, and unlike a pure one-design where everyone has the same equipment it will take some experience, time, and money to converge on rig designs for the smaller sails which are competitive. People seemed to use either no2 or no3 rigs yesterday, and I photographed some of them below. The top NED and SWE boats led the field along with FIN-111 who had obviously invested in the right kind of carbon-sticks, ball-bearing thingys, and sails. It looks like it is advantageous to get both the main and jib booms as close to the deck as possible.

All of this leads to a slight illusion then when you gladly advise the newcomer that the class is cheap and uncomplicated, "you get the kit for 170eur and you are done", when in fact the competitive people swap out fins and rudders right away, and spend 4-500 euros on a set of the latest carbon-ballbearing-super-mainsail-roach-rigs. Anyone with more experience in the MicroMagic class care to comment?

IOM Radio Sailing on Youtube

Maybe the best collection ever of IOM, or any class really, radio sailing videos available online:

http://www.youtube.com/user/Kingg2855

Way to go "Kingg2855" !

Pikanto nr2-rig sailing

Had a chance to sail the PIKANTO in nr2 rig conditions today with pretty good results. More comments to follow later...

Note to self: ran out of Malin Stainless Steel Leader, 80 lbs, which we use for stays and shrouds. Must buy more. Are there any other fishing wires that are good for IOM stays/shrouds?

Looks like they have Malin here: http://www.tackledirect.com/malinleader.html

PIKANTO nr 3 sailing

Got a chance to sail PIKANTO hull nr 3 today in Turku. After a bit of servo-programming to get the travel on the HiTec winch dialled in right it was on with the deck patches and onto the water. Turns out the balance is pretty darn good as we had gusty nr1 rig weather today and the boat behaved very well in both the lighter and the stronger breeze. I missed two races because of a flat boat battery - the HiTec arm-winches demand a little more attention to batteries, wires, and connectors, since they draw quite a bit of current. After two summers of sailing a Noux with a fairly narrow 85mm chord fin the Bantock-style large-area fin (120mm chord at the root, tapering to around 70mm) feels easy to sail and difficult to stall. A bit more rudder travel, some more rig tuning, and lots of sailing routine and I feel this will become a great boat to sail.

Two non-PIKANTO pictures: In the middle of racing this dude pulls up with his muscle-motor-boat and starts to load it up with diesel. ZOMG: almost 400 liters costing more than 500 euros!

Our starting sequence was played from a USB-stick, no more trouble with wobble of the player causing the CD to jump and interrupting the sequence.

Winch drum machining video

99mm diameter winch drum for arm-winch type sheeting with powerful (e.g. HiTec) digital servos. CNC-machined in aluminium. four M3 threaded holes, weight 21 grams, price 30 euro/pcs.

PIKANTO nr 3 completed

Jari has added fittings, radio-installation, bulb, and foils to PIKANTO hull nr 3. Note the aluminium cnc-machined winch-drum for the HiTec winch-servo.

While we have developed a good looking cnc-machined steel finmould, ruddermoulds, a bumper mould, etc. we are still not producing hulls in any larger numbers for sale due to various reasons. Stay tuned.

MicroMagic 2010 Ranking 3, Lohja

12 boats completed 6 races before lunch in light and shifting conditions. After lunch there was no more sailing because of heavy lightning, thunder, and lots of rain.

The ball-raced gooseneck with ballbearings around the mast looks nice. Riku had a new boat with aluminium mounts for the sheet and rudder servos instead of the standard plywood ones. Many boats had new "VAM" sails.

CNC-turned stainless steel IOM bulb

CNC-turned from stainless steel, this is a 400mm long and 38mm diameter IOM keel bulb. A slot will be milled in the middle for the keel fin. Unlike a lead-bulb this one will require no surface filler/sanding/painting. But the density (compared to water) of stainless steel is 8 at most, while lead bulbs can be close to 11 (depending on the lead-alloy), which means the volume of this bulb is slightly larger.