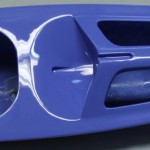

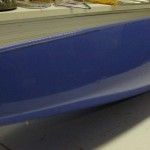

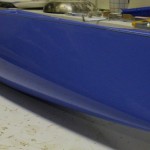

We are finding that different colour pastes result in gelcoats with widely different ability to cover and produce a nice finish. This means we'll have to do a bit of experimenting and then only produce boats with colours that are easy to work with.

Hull nr. 3 "Yellow Submarine" was moulded last weekend and it will be interesting to see the result. Against the black of the mould-gelcoat the yellow doesn't seem to cover too well (compare to hulls 1 "sky-blue" and 2 "battleship-grey").

These pictures are taken just after painting the gelcoat into the mould. We make the gelcoat from the moulding-resin by adding colloidal silica and the colour paste.

Making hull nr3 was a 7 hour process:

10:00 arrive at workshop, do a bit of cleaning and preparation

11:00 start mixing and applying gelcoat to moulds, takes about an hour for deck and hull.

12:00 - 14:00 wait... gelcoat is in the mould and needs to cure. not much to do now(eat lunch, cut fibers, etc).

14:00 start moulding. The hull is fairly quick and only takes an hour or so

15:00 mould deck. This is more tricky with a lot of different small bits of fibers required, takes more than an hour usually

~16:00 fibers are in both moulds, close the moulds and start on the join between deck and hull

17:00 all done. Leave moulds and new boat to cure.