We are finding that different colour pastes result in gelcoats with widely different ability to cover and produce a nice finish. This means we'll have to do a bit of experimenting and then only produce boats with colours that are easy to work with.

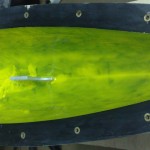

Hull nr. 3 "Yellow Submarine" was moulded last weekend and it will be interesting to see the result. Against the black of the mould-gelcoat the yellow doesn't seem to cover too well (compare to hulls 1 "sky-blue" and 2 "battleship-grey").

These pictures are taken just after painting the gelcoat into the mould. We make the gelcoat from the moulding-resin by adding colloidal silica and the colour paste.

Making hull nr3 was a 7 hour process:

10:00 arrive at workshop, do a bit of cleaning and preparation

11:00 start mixing and applying gelcoat to moulds, takes about an hour for deck and hull.

12:00 - 14:00 wait... gelcoat is in the mould and needs to cure. not much to do now(eat lunch, cut fibers, etc).

14:00 start moulding. The hull is fairly quick and only takes an hour or so

15:00 mould deck. This is more tricky with a lot of different small bits of fibers required, takes more than an hour usually

~16:00 fibers are in both moulds, close the moulds and start on the join between deck and hull

17:00 all done. Leave moulds and new boat to cure.

Anders,

How do you join the deck to hull ? Do you apply glass tape through the apertures in the deck moulding ?

Congratulations on a fantastic website...

Andy

Apologies Anders, I have seen you notes detailing the joining process with the 40mm tape eslewhere...

Andy

The way we lay up the boat probably deserves its own post, since many people have asked. There's a short description in the comments here:

http://www.anderswallin.net/2009/12/polished-pikanto-hull-mould/