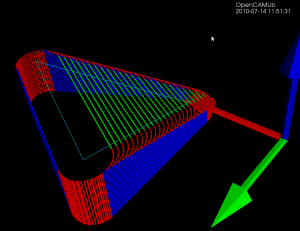

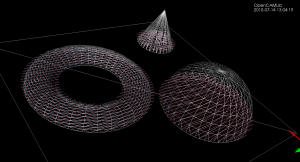

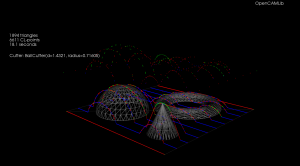

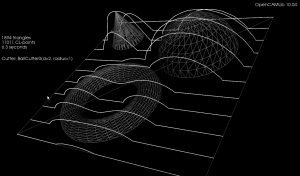

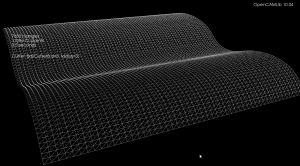

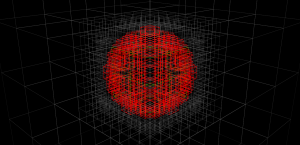

After the proof-of-principle waterline experiments two days ago I've modified the KD-tree search so that triangles overlapping with the cutter can be searched for in the XZ and YZ planes (in addition to the XY-plane, which was needed for drop-cutter). This dramatically reduces the number of triangles which go through the pushCutter function and makes it possible to run some tests on small to medium STL files.

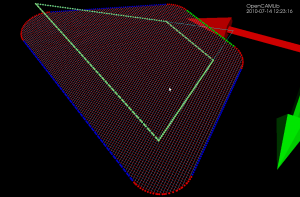

Currently all the CL-points come out of the algorithm in an undefined almost random order. I'm just plotting them all and they are closely spaced, so it looks like a path, but the algorithm has no idea in which order the CL-points should be visited. Before these waterlines are of any use a second algorithm is required which inspects the weave and (a) comes up with the number of "loops" or "rings" (what should we name these?) at each waterline and (b) sorts the CL-points in each loop into the right order. The upstream user of these waterline loops can then decide in which order to visit the waterlines at each z-height, and within one waterline in which order to visit the loops. Any CL-point in a loop is as good as any other, so the upstream user can also choose where to start/stop the toolpath around the loop.

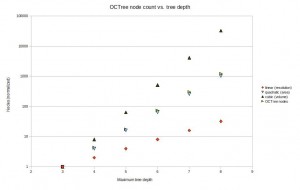

My idea for this is to turn the weave in to a graph and use the Boost Graph Library which has a function for returning the number of connected components (part (a) above), and then perhaps the All-pairs shortest path algorithm to find adjacent CL-points (part (b) above). Any other ideas?

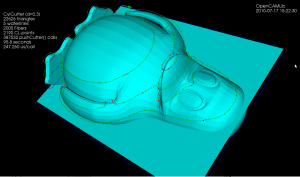

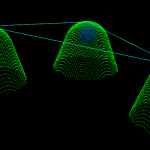

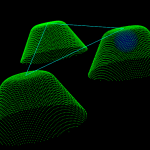

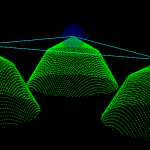

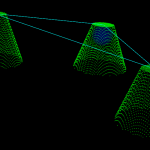

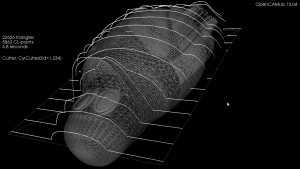

Here's the obligatory Tux example, where it took 96 seconds to generate five waterlines.