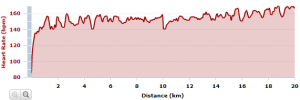

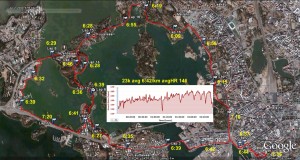

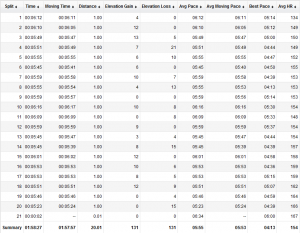

The plan was to run slower and longer, but all those hills in the first (and last) 7k which cause the HR-curve to jump up and down made me turn around at 10k.

Links - 2010 Jul 8

- Rebel T2i/550D Firmware 1.0.8 -

- Turning a hollow spiral candlestick -

- Receiving weather satellite transmissions -

- Canon releases firmware updates for EOS-1D Mark IV and Rebel T2i -

- The manufacturing future -

- Planck unveils the Universe -

- Dale talks to Liam Casey about manufacturing in China -

- Lo Res Project -

- Man Actually Wins Internet Debate (Also Builds Awesome Car) -

- RADICAL - experimental RC catamaran/trimaran from Brazil Germany

- How-To: Build a star-tracker for your camera -

- Quantum Computing – cool new video! -

- Pixel casting machine -

- Homemade blow-molding gun -

- Microscopic photos of the iPhone 4 Gyroscope -

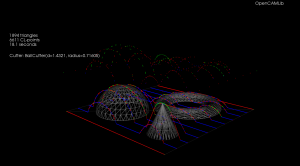

Cutsim Tux

Octree-based cutting simulation

Here's an initial test of octree-based cutting simulation:

If you turn up the resolution to eleven, where it starts to be useful and not so grainy, the calculation of the tool-swept volume, which we subtract from the stock at each move, becomes too slow.

See also octree operations.

Download a short clip with a depth=10 tree: OUTPUT (it's also on youtube, but a 2s clip on youtube doesn't work very well: http://www.youtube.com/watch?v=G0RYS9FcqR0)

some screenshots:

Line filter for opencamlib

When generating toolpaths with drop-cutter ("axial tool-projection", if you like fancy words) the path ends up being composed of lots of short linear segments. It makes sense to filter this list of points and take out any middle points that lie on a straight line between neighboring points. Here's a first attempt at such a line-filter.

The lower points is the raw output from drop cutter, while the filtered points are offset vertically for clarity. There are 6611 CL-points in the raw data, but only 401 CL-points after filtering.

The next step is to come up with an arc-filter which detects circular arcs in the list of CL-points. All CNC-machines have G2/3 circular arc motion in the principal planes (xy, xz, yz). Then the number of moves will go even further down from 401 points.

This is just something to live with, having chosen the triangulated model approach to CAM. First we have pure and exact shapes in CAD which get tessellated into zillions of tiny triangles, from these we generate a sampled toolpath consisting of lots and lots of points, and finally we filter to get back those "pure" "exact" and "nice" line-segments and arcs.

The relevant part of the code looks like this. It might be a bit prettier to use the remove_if STL algorithm? Also, there's no check that p1 actually lies between p0 and p2.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 | typedef std::list<clpoint>::iterator cl_itr; cl_itr p0 = clpoints.begin(); cl_itr p1 = clpoints.begin(); p1++; cl_itr p2 = p1; p2++; for( ; p2 != clpoints.end(); ) { Point p = p1->closestPoint(*p0, *p2); if ( (p- *p1).norm() < tol ) { // p1 is to be removed p1 = clpoints.erase(p1); p2++; } else { p0++; p1++; p2++; } } |

full code here.

Pikanto nr2-rig sailing

Had a chance to sail the PIKANTO in nr2 rig conditions today with pretty good results. More comments to follow later...

Note to self: ran out of Malin Stainless Steel Leader, 80 lbs, which we use for stays and shrouds. Must buy more. Are there any other fishing wires that are good for IOM stays/shrouds?

Looks like they have Malin here: http://www.tackledirect.com/malinleader.html

23 k Friday long run

Radians vs. DiamondAngle

Over at Freesteel, Julian talks about using a "DiamondAngle" in the interval [0,4] for representing a plane angle instead of the usual radian in [0,2PI]. The argument is that using diangles there is an exact floating-point number for north/south/east/west, and that conversion to/from diangles is faster because it doesn't involve calling trigonometric functions.

I did a test with this, converting 10 million uniformly distributed radian angles to/from unit-vectors, and ditto for diangles. Converting diangles to unit-vectors is ca 25% faster than calling sin() and cos(), while the reverse transform is almost 3x faster than calling atan2. Runtimes in seconds below:

compare radians to dianglescos/sin 1.13atan2 0.78dia2vec 0.83vec2dia 0.27

Lathe tool-post and tools

My order from RDG tools arrived today. The quick change tool post if T00, or Myford-size, for 12 or 12.7 mm tools, and included three holders. I also got a pack of five extra holders for a total of eight. There's a set of seven 12mm carbide-insert turning tools, and an internal threading tool for metric (60 degree) threads.

The order with ER11 and ER25 straight-shank collet chucks including sets of collets from CTC hasn't arrived yet. Since it comes from Hong Kong it will probably go through customs and I will have to pay VAT...

Links - 2010 Jul 1

- Massive printable "Tree of Life" graphic for free download -

- Microsoft .NET vs Java - trailer [Video] -

- Tool path generation and modification for constant cutting forces in direction parallel milling -

- Strategies for three-dimensional particle tracking with holographic video microscopy -

- Longitudinal optical trapping and sizing of aerosol droplets -

- Stable trapping and manually controlled rotation of an asymmetric or birefringent microparticle using dual-mode split-beam optical tweezers -

- video: Tetris theme song - cnc music with stepper motors!

- 06/25/10 PHD comic: 'Call for Papers!' -

- Nikkor 180mm f/2.8 ED AI-S Lens Review -

- Plugin: Fredo's Curviloft 1.0a (Beta) Now Available -

- Tool path generation for triangular meshes using least-squares conformal map -

- The Intellectual Property Implications of Low-Cost 3D Printing -

- Machining a horizontal Stirling engine -

- “On the decline of mathematical studies, and the sciences dependent upon them” -