- Phlatscript – Sketchup to G-code -

- Nokia E7 starts shipping December 10th (update: December 2010) - can we get this one with meego please? now?

- Kingston introduces 256GB SSDNow V100 SSD for $490 -

- Digital calipers tear down -

- N900 -

- Indamixx 2 Atom-powered MeeGo tablet touts rockstar looks, $999 price tag -

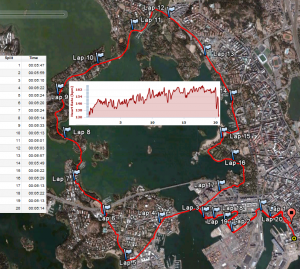

- Garmin Forerunner 210 Review -

- $19.90 - 150mm Stainless Steel Digital Caliper (in/mm LCD) -

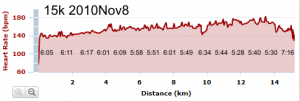

Monday Fifteen

Bulbs

Some IOM bulbs from the new moulds.

Links - 2010 Nov 4

- Nokia N8 Teardown Shows Tough Phone, Great Camera -

- Dreamslide, a Seatless Bike That You Surf -

- Future Shock: Nokia Research Touts 5 Innovative Mobile Interfaces -

- 70 Terabytes of Homebrewed Storage is a Beautiful Mess -

- Samsung Galaxy Tab: Cheaper Than iPad, But Not Really - huh? this thing is $400 in the US and costs 898 euros at the local verkkokauppa.com. wtf.

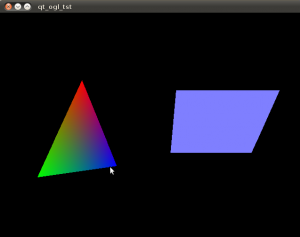

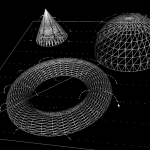

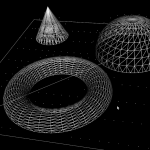

Qt and OpenGL test

It looks like there is no efficient way of updating (adding and removing) triangles in a polydata-surface in VTK, so for the cutting-simulation I am looking at other visualization options. Despite all the tutorials and documentation out there on the interwebs it always takes about two hours to get these "Hello World" examples running...

Download a zip-file with the source and cmake file: (This compiles and runs on Ubuntu 10.04LTS) qtopengl

Tuesday Twenty

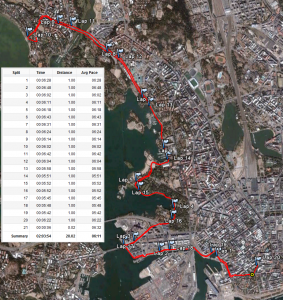

LSD - long slow distance. It's good for you.

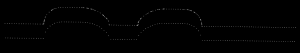

Adaptive sampling drop-cutter

Inspired by this post on the pycam forum and by this 1993 paper by Luiz Henrique de Figueiredo (or try another version) I did some work with adaptive sampling and drop-cutter today.

The point based CAM approach in drop-cutter, or axial tool-projection, or z-projection machining (whatever you want to call it) is really quite similar to sampling an unknown function. You specify some (x,y) position which you input to the drop-cutter-oracle, which will come back to you with the correct z-coordinate. The tool placed at this (x,y,z) will touch but not gouge the model. Now if we do this at a uniform (x,y) sampling rate we of course face the the usual sampling issues. It's absolutely necessary to sample the signal at a high enough sample-rate not to miss any small details. After that, you can go back and look at all pairs of consecutive points, say (start_cl, stop_cl). You then compute a mid_cl which in the xy-plane lies at the mid-point between start_cl and stop_cl and, call drop-cutter on this new point, and use some "flatness"/collinearity criterion for deciding if mid_cl should be included in the toolpath or not (deFigueiredo lists a few). Now recursively run the same test for (start_cl, mid_cl) and (mid_cl, stop_cl). If there are features in the signal (like 90-degree bends) which will never make the flatness predicate true you have to stop the subdivision/recursion at some maximum sample rate.

Here the lower point-sequence (toolpath) is uniformly sampled every 0.08 units (this might also be called the step-forward, as opposed to the step-over, in machining lingo). The upper curve (offset for clarity) is the new adaptively sampled toolpath. It has the same minimum step-forward of 0.08 (as seen in the flat areas), but new points are inserted whenever the normalized dot-product between mid_cl-start_cl and stop_cl-mid_cl is below some threshold. That should be roughly the same as saying that the toolpath is subdivided whenever there is enough of a bend in it.

The lower figure shows a zoomed view which shows how the algorithm inserts points densely into sharp corners, until the minimum step-forward (here quite arbitrarily set to 0.0008) is reached.

If the minimum step-forward is set low enough (say 1e-5), and the post-processor rounds off to three decimals of precision when producing g-code, then this adaptive sampling could give the illusion of "perfect" or "correct" drop-cutter toolpaths even at vertical walls.

The script for drawing these pics is: http://code.google.com/p/opencamlib/source/browse/trunk/scripts/pathdropcutter_test_2.py

Here is a bigger example where, to exaggerate the issue, the initial sample-rate is very low:

Links - 2010 Oct 28

- Bee Solves Travelling Salesman Problem -

- Andy Rubin responds to Steve Jobs with a coded tweet -

- Programmer problem solving sequence -

- The Difference Between Twitter and Facebook -

- Student Hides Rick Astley's Song In College Paper [Video] -

- Creativity WIN / Answer FAIL -

- The more the merrier. - 6ch Tx/Rx 2.4GHz radio control for $49.95, hmm...

- Physicists Discover Universal "Wet-Dog Shake" Rule -

Tuesday Twenty

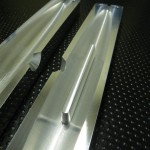

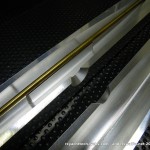

New IOM bulb moulds cnc-machined

Jari made these new IOM bulb-moulds over the weekend. CNC-milled in aluminium. Circular cross-section with a NACA0010-34 profile (similar to my 2005 design), length ca 360mm. Designed with a central stiffening brass rod. Check out rcyachttech.webs.com for more cnc-machined moulds and parts.

See also casting notes from 2003.