What's the simplest possible way to install the radio components in the boat?

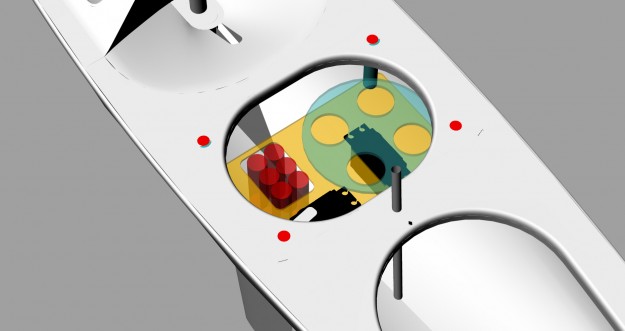

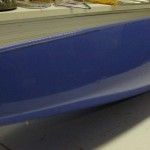

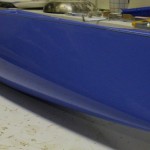

Here's an idea: Use an FR4 glassfiber PCB-board (yellow) cnc-cut to the correct shape and with cut-outs for the winch, rudder servo, and batteries. Mount it to the deck with long M4 bolts with Y-head screws that mount flush to the deck. Use 50 mm long 10 mm diameter aluminium spacers (blue) to position the plate at the correct height below the deck.

Simple: yes! Works with both HiTec and RMG winch: yes! Easy to manufacture: yes!

Comments?

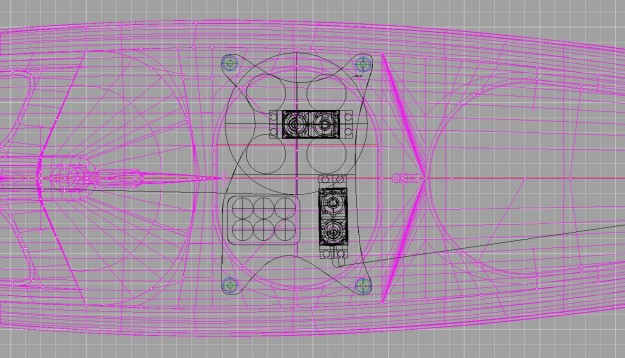

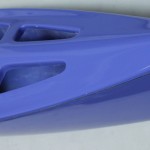

Update: top view of a shaped radio-board:

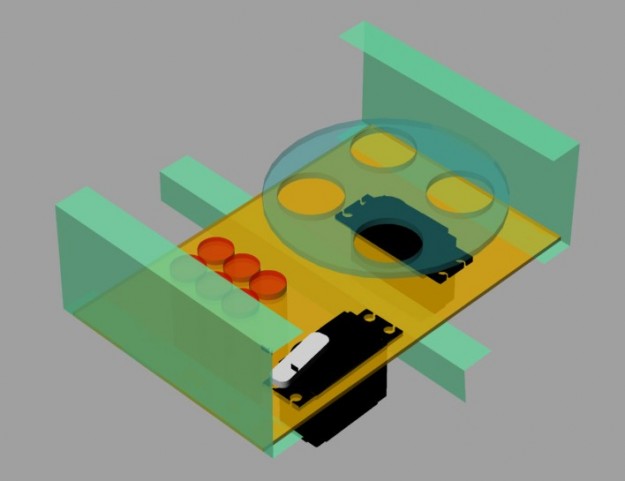

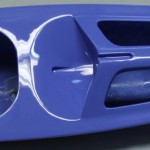

Update 2. Here I have drawn 50mm deep U-shaped glassfiber supports that hold the radio-plate from the sides. Also, there is an L-shaped beam which is glued to the finbox and to the sheet-tube which gives additional support to the radio plate: