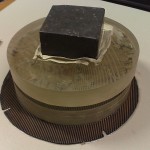

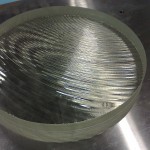

After a few (2-3) more hours of polishing with the full-size lap the mirror was fully polished. No holes or marks can be seen in the mirror surface with an upside-down 25mm eyepiece. Final polishing progressed rapidly when we used a weight (4-6 kg) on top of the mirror/tool.

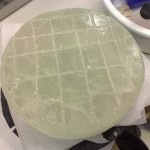

The following task is called figuring, where the surface is taken from a sphere to a praboloid. Following advice from experienced mirror makers we are doing this with a smaller pitch-lap which is about 60% of the diameter of the mirror. We're using W-shaped strokes mostly in the middle of the mirror.

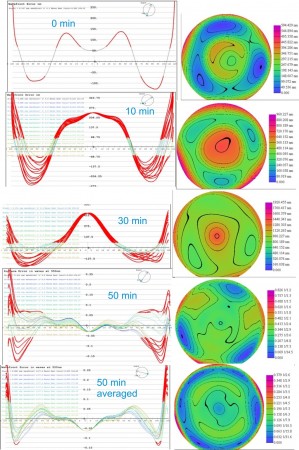

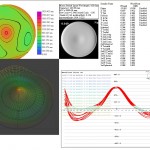

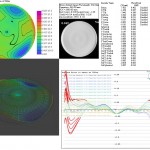

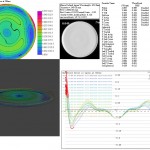

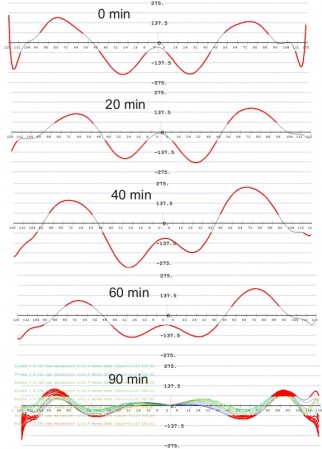

This picture shows the progress over a few 10 min or 20 min figuring sessions, with measurements taken after each session.

The main difference between a sphere and a praboloid is evident. The paraboloid is deeper in the middle, so the error plots above show a 'hill' at the centre which needs to be polished down. The top four measurements are single measurements and show a significant amount of distortion with three lobes at 120 degrees apart. I'm not sure where this originates yet. The final measurement at the bottom is an averaged one where we turned the mirror 90 degrees between each measurement, and shows little or no hills or valleys at 120 degrees apart. We are now at 1/17 wave rms error, which seems OK. The mirror is still too high at the very edge, along an 8mm wide strip in from the edge, which we will try to correct tomorrow.