The third production PIKANTO hull is red.

Elastosil M4503 Bumper

Elastosil M4503 is a condensation-curing soft white silicone I am now using for the PIKANTO bow bumpers. The RTV-615 I used earlier was an addition-curing silicone and cured in 60 minutes at +100C. This one will not cure faster at an elevated temperature. The datasheet suggests 24 h at room temperature, but I found 48 h was needed.

MicroMagics @ Helsinki Boatshow 2010

Links - 2010 Feb 11

- Cultivate Teams, Not Ideas -

- Geometric modeling and tool path generation of model propellers with a single setup change -

- Jonathan Ward – MIT – Machines That Make -

- Canon EOS 550D Preview -

- Rebel T2i Announced. -

- Canon EOS Rebel T2i/550D Hands On -

- Canon EOS Digital Rebel T2i -

- 1D Mark IV Review -

- The iPad is the iPrius: Your Computer Consumerized -

- Geeking Out in 3D -

- Chapter 4 -

Translucent Two

The second PIKANTO production hull was taken out of the mould today. It's made with a clear gelcoat and will be painted later.

I've created a PIKANTO-Page which will have details about the project and future sales.

Sunday Seven

Links - 2010 Feb 4

- Get Seriesous - Pt. 1 -

- Get Seriesous - Pt. 2 -

- Get Seriesous - Pt. 3 -

- Get Seriesous - Pt. 4 -

- Chapter 4 - who can make things like this up??

- M42 HDR Composite -

- First Impressions: Lenovo ThinkPad T410 -

- Comercial 3D printers, a look inside -

- Canon Rebel T2i [CR2] -

- Why Open Source Will Rule Scientific Computing (Part 2) -

- Why Open Source Will Rule Scientific Computing -

- FOSS CAD and 3D Modeling Software? -

- Quadtree-array-based workpiece geometric representation on three-axis milling process simulation -

- How to Suck at Facebook -

- Femtonewton Entropic Forces Can Control the Formation of Protein-Mediated DNA Loops -

- Generating collision-free tool orientations for 5-axis NC machining with a short ball-end cutter -

- The vired iPod (comic) -

Wires, wires, wires…

Number of wires from servo-motor to controller on my lathe build: 19.

1: Motor power U

2: Motor power V

3: Motor power W

4: Hall sensor +5V

5: Hall sensor U

6: Hall sensor V

7: Hall sensor W

8: Hall sensor GND

9: Encoder +5V

10: Encoder A

11: Encoder B

12: Encoder Z

13: Encoder GND

14: +Limit switch Common

15: +Limit switch N.O.

16: +Limit switch N.C.

17: -Limit/Home switch Common

18: -Limit/Home switch N.O.

19: -Limit/Home switch N.C.

The motor currents go through the AMP-connecor, everything else through the 25-pin D-connector.

I'm glad the lathe only has two servos (and a spindle), I would go mad with a 5-axis machine...

Winter

It is not very often you see this kind of snow-plower-winter-tram!

7k walk from Kumpula to downtown. Google earth inserts a golf-playing green man at every kilometer.

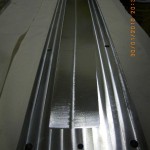

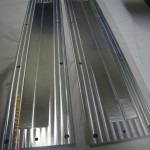

RG65 Fin and Rudder moulds

We've done the CAD design, CAM-toolpaths, and CNC-machining for a set of RG65 model yacht (looks roughly like this) fin and rudder moulds. They will be shipped to the customer on Monday.

From time to time I get enquiries about making moulds like this, for fins, rudders, bulbs, etc., from people around the world. Usually by people who've gone to a professional mould-shop or cnc-workshop with their drawings, and suffered a bit of sticker-shock when they've seen the quote. For this set of moulds we asked 500 euros, which is not a lot I claim. Production and delivery in one week or less after the final CAD-drawings were available.

If you're interested in CNC-cut moulds in aluminium or steel, please send your ideas, preferably a CAD drawing, and I'll send you a rough quote. Keep in mind that our machine has a working XY envelope of ca 500x200 mm, so no single parts can be bigger than this. There are lots of examples of what we do in this blog, you might like: bumper mould (2010 Jan), Rudder mould (2009 Dec), IOM MDF plug (2009 Feb), Microscope part (2009 Sep), IOM Fin moulds (2008 Jun), Telescope rings (2008 May).