Fine-grinding of the mirror has progressed without problems. Around 1.5 hours of work per grit-size was enough to achieve a uniform surface roughness. After the finest grit, 15 micron Aluminium oxide in our case, it's time to polish the mirror using a Pitch lap and cerium oxide.

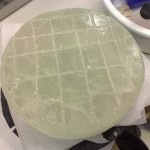

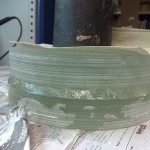

We heated around 500g of pitch on an electric plate. Note the tube that sucks away the fumes (normally used when soldering). Pitch is an interesting material to play around with, hard and brittle when cold, almost as runny as water when hot, and all kinds of viscosities and 'feel' in between. The mirror and glass tool were heated in an oven to around 65 C and a dam of paper masking tape was added to the tool. After pouring the pitch we waited for it to cool a bit and then made some channels using a steel ruler. Then the lap was pressed, mirror on top, with water and soap covering the surfaces to avoid sticking. Finally when the lap had cooled using a sharp knife the edges were bevelled and the channels re-opened.

About 10 hours of polishing now follows...

Here's a nice how-to page for someone looking for instructions:

http://www.atm-workshop.com/pitch-lap.html