Inspired by the drawings and design info available on my site, and by Michael Scharmers article on iom-nordic.org, Peter Trimmer (AUS) is putting together a wooden Noux. He sent me some pictures of his progress.

Here is the plug for the bulb turned out of wood. A mould around this from plaster will be made and the bulb will be cast in lead.

The hull being planked with 4mm balsa. Peter didn't reduce the shadows from the plan before planking so the boat will end up a little bigger than designed - a Fat-Noux 😉

The cockpit deck, also planked in balsa.

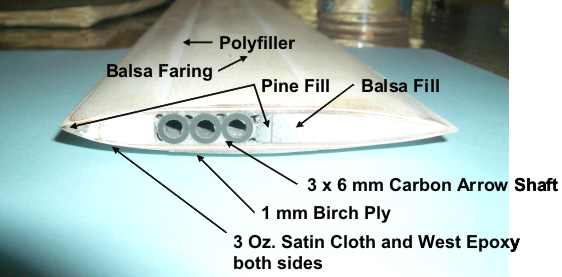

Peters novel idea for a homemade fin, covered in wood ofcourse - true to the style of the boat !:

"3 -6mm carbon tubes sanded down on two sides a bit and glued between 1mm ply skins with balsa packing the spaces - all soaked in West Epoxy and clamped between full length temporary balsa formers. It has turned out with all the necessary stiffness even before I glass it."¨

Looks good, my only concern is that fin thickness is a critical parameter for performance so the homebuilt fin must be around the same thickness, 6-7 %, as a full-carbon fin. With a chord length of 85mm this means a thickness of only around 5-6mm.

The finished fin with the rudder. The rudder requires less stiffness so it has a plywood core with balsa outer skins covered with glassfiber cloth.

More to follow later hopefully...

Hello they are fabio from Perugia (Italy) and me stò autocostruendo a hull IOM with several difficulties, I have seen the design of the rudder, is possible to have the format in GCODE for my autocostruita machine? hello and good wind

Hi Fabio,

In principle that would be possible, but it would not be a very practical way of distributing the design. To generate G-code for a CNC machine I would need to know what kind of milling cutter you are using (cylindrical end-mill, ball-nose, bull-nose etc) what diameter it has, how fast your machine is able to move, what spindle rpm you are using, what size stock material you intend to use etc. etc.

so in reality it's usually not practical to use G-code that someone else has created for you.

There should be an IGES or DXF drawing attached to this post:

http://www.anderswallin.net/2005/12/rudder-design-for-noux-iom/

try importing that into your CAM program, and generate your own G-code.

If you don't have a CAM program, try finding someone close to you that has one - so you can go through a couple of iterations of changing parameters etc. which might be necessary to get the mill to cut the mould right.

regards,

Anders