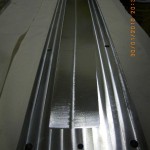

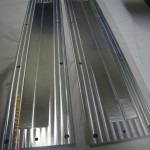

We've done the CAD design, CAM-toolpaths, and CNC-machining for a set of RG65 model yacht (looks roughly like this) fin and rudder moulds. They will be shipped to the customer on Monday.

From time to time I get enquiries about making moulds like this, for fins, rudders, bulbs, etc., from people around the world. Usually by people who've gone to a professional mould-shop or cnc-workshop with their drawings, and suffered a bit of sticker-shock when they've seen the quote. For this set of moulds we asked 500 euros, which is not a lot I claim. Production and delivery in one week or less after the final CAD-drawings were available.

If you're interested in CNC-cut moulds in aluminium or steel, please send your ideas, preferably a CAD drawing, and I'll send you a rough quote. Keep in mind that our machine has a working XY envelope of ca 500x200 mm, so no single parts can be bigger than this. There are lots of examples of what we do in this blog, you might like: bumper mould (2010 Jan), Rudder mould (2009 Dec), IOM MDF plug (2009 Feb), Microscope part (2009 Sep), IOM Fin moulds (2008 Jun), Telescope rings (2008 May).