Were stretching a 13 kb DNA-construct between two optically trapped beads. This isn't a video of the experiment itself, but of some entangled beads we found in an old sample. The beads are 3 or 2 micron in diameter, and we hold on to the middle big bead with the optical trap while moving around the microscope stage. Hydrodynamic drag stretches out the chain of entangled beads. Not much, if any, scientific value, but a fun video nevertheless.

Links 2009jan27

Random links:

A VOR-like model yacht under construction: http://riku.ullatus.com/vene/

Cleaning glass: http://www.arksky.org/asoclean.htm

The Most Exciting Future Biophysics Tool

Contribute to science by playing FoldIt: http://fold.it/portal/

A 10" Ritchey-Chretien telescope http://www.kehusmaa-astro.com/2009/01/22/deep-sky-instruments-rc10c-arrived

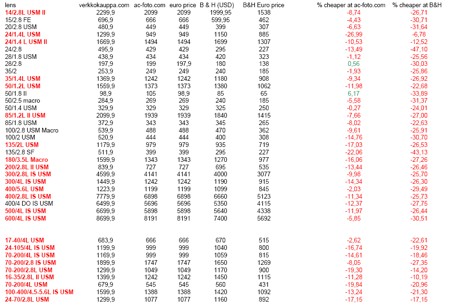

The price of Canon lenses

I'll be visiting the US again in a month or so - a good opportunity to do some photography shopping. I've made a list of a subset of EF-lenses by Canon and looked up the prices at local webshop verkkokauppa.com, the German ac-foto.com, and compared these to bhphotovideo.com. The conclusion from the histogram below is something I sort of knew beforehand, but I'm still a bit shocked by how big the price difference is.

Compared to Finland, it's (10 +/- 7) % cheaper to buy your lenses from Germany. And it's a huge (38 +/- 9) % cheaper to get them from the US! (I've used the current dollar/euro rate of 1.3)

(click image above to download a pdf)

Check this out: EF-135 f/2.8 SoftFocus, 71% cheaper in the US, or look at the EF-28/2.8, 63 % cheaper!

disclaimer: this is not the complete set of EF-lenses, prices checked from the corresponding websites 26.1.2009, your mileage may vary.

Countries visited

visited 17 states (7.55%)

Create your own visited map of The World or try another Douwe Osinga project

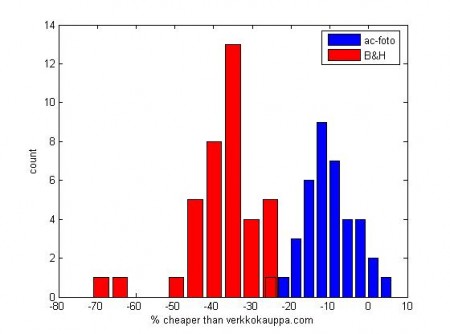

Polishing tools

A few pictures and some notes on the polishing tools which we've used for the 240mm F/6 mirror for the Newtonian telescope we are making.

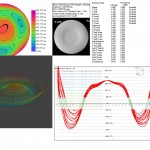

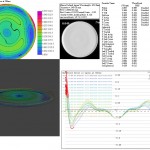

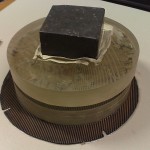

This is the full-size pitch-lap on top of the mirror. It's important to have good contact between the tool and the mirror at all times, so the pitch is pressed to conform to the mirror before each polishing sessions. This can be done either at room temperature, called cold-pressing, or by first heating the pitch-lap and the mirror in e.g. hot water, which is called hot-pressing.

We've usually hot-pressed the lap just after pouring it, and each time we have had to re-open the channels. The best way to open the channels we've found is with a saw - seems to work nicer and cleaner than with a sharp knife. When the lap has good contact with the mirror only cold-pressing is required before each polishing session. The image shows cold-pressing with a 20 kg weight on top of the tool, perhaps a bit on the heavy side.

This is the smaller weight, about 5.5 kg, we use on top of the tool when polishing. There's a significant difference in the speed of polishing with and without this weight. At first we did about 10 hours of polishing without a weight, but I'm sure this time could have been cut in half by use of this weight (or something slightly heavier). Ideally the weight should be evenly distributed over the mirror/tool, a steel disk of the same diameter would be good. But we haven't noticed any significant distortion of the mirror or tool with this smaller lead-weight.

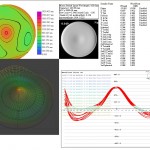

When figuring the mirror from a sphere to a paraboloid this smaller 60% tool is used. Here it's cold-pressed against the mirror. Since this is an F/6 mirror the correct paraboloid shape is very close to the spherical shape that the mirror has at the end of polishing. We've found about 50 minutes of work with this tool is enough.

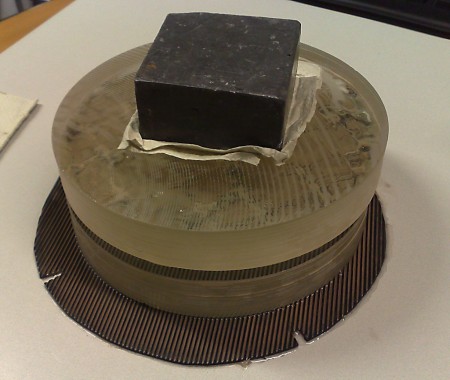

Figuring

After a few (2-3) more hours of polishing with the full-size lap the mirror was fully polished. No holes or marks can be seen in the mirror surface with an upside-down 25mm eyepiece. Final polishing progressed rapidly when we used a weight (4-6 kg) on top of the mirror/tool.

The following task is called figuring, where the surface is taken from a sphere to a praboloid. Following advice from experienced mirror makers we are doing this with a smaller pitch-lap which is about 60% of the diameter of the mirror. We're using W-shaped strokes mostly in the middle of the mirror.

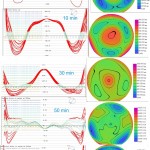

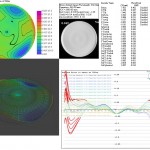

This picture shows the progress over a few 10 min or 20 min figuring sessions, with measurements taken after each session.

The main difference between a sphere and a praboloid is evident. The paraboloid is deeper in the middle, so the error plots above show a 'hill' at the centre which needs to be polished down. The top four measurements are single measurements and show a significant amount of distortion with three lobes at 120 degrees apart. I'm not sure where this originates yet. The final measurement at the bottom is an averaged one where we turned the mirror 90 degrees between each measurement, and shows little or no hills or valleys at 120 degrees apart. We are now at 1/17 wave rms error, which seems OK. The mirror is still too high at the very edge, along an 8mm wide strip in from the edge, which we will try to correct tomorrow.

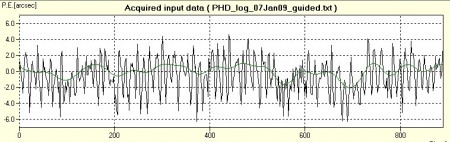

First Autoguiding test

When photographing the sky using exposures of a minute or more, to avoid star-trails, it's important that the mount tracks the movement of the stars (or rather the movement of the earth!) very accurately. In practice it's very hard to build a mount tha tracks to the required 1" (one arc-second) or better precision. Some new mounts that use direct-drive motors and accurate (expensive!) encoders are probably up to this, but they cost 15 keur or more. All reasonably priced mounts use worm-gears, and show more or less pointing error. With an expensive (3-5 keur) mount it might be possible to image unguided for 1 or 2 minutes, but all worm-gear driven mounts show pointing errors during long (say 10 min) exposures.

So a technique called auto-guiding is used. In addition to the main camera you are imaging with you have another camera that takes pictures continuously, a computer analyzes these pictures, and sends commands to the mount to keep the guide-star in the same position on the guide-camera chip. Read more about this from someone who actually knows what he is talking about at Uncle Rod's Astro Blog.

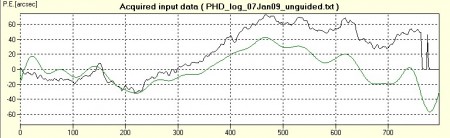

If you disable the guide-commands the camera can just track the guide-star, and you can plot a graph of what's called the periodic-error of the mount. This error is due to imperfections in the worm-drive, and on good mounts it can be as low as 10". The error is periodic and repeats on each revolution of the worm-gear, which is every 4-10 minutes on most mounts.

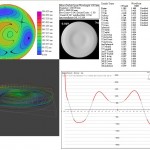

Here are my results from this evening. This is an EQ6 mount which normally doesn't support autoguiding, so I've soldered in the required ST4-connector following these instructions. I'm using a Rubinar 500/5.6 as the guide-scope, and a QHY5 camera. Guiding with PHDGuiding and the results analyzed with PEAS. Keep in mind that these are my first ever autoguiding results, and it was around -13 C outside so I was not keen on repeating the measurement or tuning any parameters. PHDGuiding lost the guide-star towards the very end.

about +60" and -30", that's some error! Compare to the finnish database here, or this french page with a lot of data (will add link when I find it...).

Here's the same run in closed-loop, with guiding commands enabled, and PHDGuiding continuoysly trying to point the mount at the guide-star. A lot better, note how the Y-axis has 10-fold smaller values. Looks like the loop overshoots and 'hunts' for the guide-star, so this might still improve with some tuning.

With my Canon 20D on my imaging scope, an 80mm f=600mm refractor, this field of view calculator gives a sampling of 2.2 arc-seconds/pixel, so as long as the error stays within or at this level there should not be a problem.

Elk

Needs Guiding

An 8 minute exposure through a 200mm lens. Unguided EQ-6 mount. With this mount and my polar-alignment skills it seems that a 60s exposure is the maximum achievable at 200mm.

I have a QHY5 guide-camera and a 500/5.6 Rubinar which I plan to use for auto-guiding which will (I hope!) put an end to the squiggly stars.