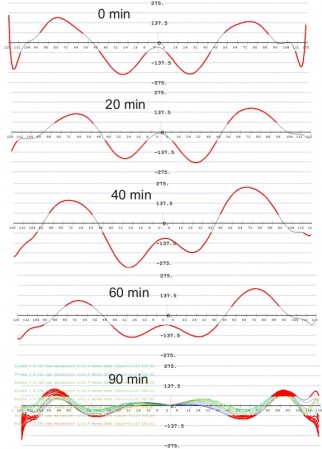

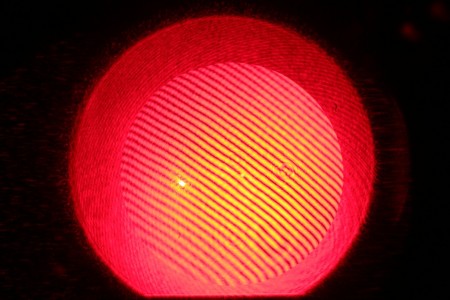

Out pitch-lap is one that really doesn't work when polishing mirror-on-top. Should have realized that yesterday. The first two 20min sessions today were spent making the shape of the mirror worse, before we switched to tool-on-top for the last 30min + 30min. Suddenly it all goes much better, and we are back to a nice better than 1/10 wave sphere. We still see small dots from a laser-pointer reflection, so it's not time for figuring just yet.

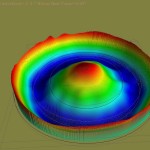

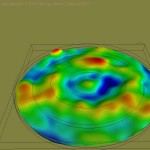

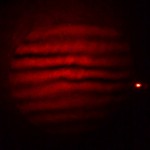

The graph shows the wavefront error in nm, compared to a sphere. The Foucault images on the left are simulated from a zernike fit to the surface measurement.