Now that we have the new spindle on our mill, and the linear rail+ballscrew conversion for the Z-axis have been working for a while, it's time to upgrade the X and Y axes.

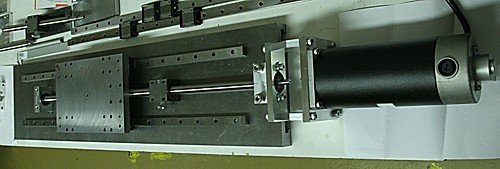

Jari has made some good progress on the table/X-axis. The IKO 15 mm linear rails are mounted, we've machined and attached the bearing holders for the ballscrew, made a motor mount for the servo, and also worked on the steel saddle plates. The new talbe is much bigger than the old one, and will allow about 500mm of X-axis movement. That's going to be enough to machine fin and bulb moulds for an IOM in one go - something that we can't do right now.

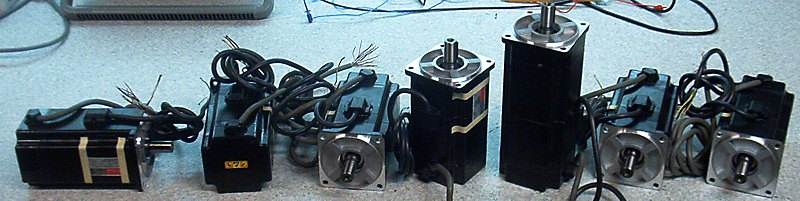

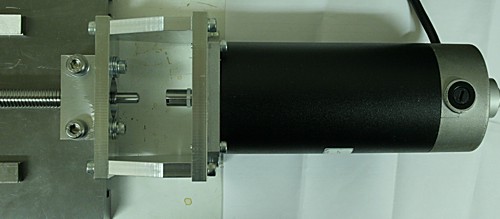

Here's a close-up of the motor mount, all parts machined from aluminium using our own mill. There's room for a coupler between the 12mm motor shaft and the 8mm ballscrew end. The motors we are using are 1.6 Nm continuous torque DC brush motors from Camtronics. Keeping to the KISS principle, we are hoping the motors are strong enough to work in direct-drive (no belt reduction or gears).

This photo shows the ballscrew (16mm diameter, 2.5mm pitch, from metallstore.de), the ball-nut, and the X-saddle plate with some steel bars under it to make room for the ballnut. Next up is a similar assembly for the Y-axis. That's going to be a bit more complicated since the parts will eventually have to be mounted on the very mill we are making them with! Hopefully not too many iterations of disassembly/assembly will be required...

Jari has also made a new tool-holder:

Jari has been busy planning and building a new spindle for

Jari has been busy planning and building a new spindle for