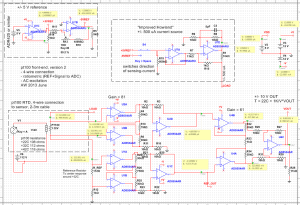

Here is version two of a precision pt100 frontend for temperature measurements between +22C and +42C. The circuit uses a 4-wire connection with a +/-500uA sensing-current. It outputs a +/-10V voltage centered around +32C by way of a 112 Ohm reference resistor. The voltage over the reference-resistor can be used to correct for drift in the sensing-current.

Compared to v1 I changed the current source to the "Improved Howland" design, and assembled the instrumentation amplifiers from zero-drift op-amps with very small input offset voltage and input bias current.

Note: The op-amp shown, AD8551/8552/8554, is a single-supply +5V op-amp and this circuit will not work as such (NI Multisim will happily simulate it though!). Use e.g. OP2177 or OPA2188 for bipolar operation at +/-12 V.

One thing I should have mentioned last time. As a general rule avoid using the non-inverting configuration on opamps. This goes double on the Howland.

If this is all just to read the temperature off of a sensor I would suggest looking at Jim Williams application notes on the subject. He did some very good stuff on that topic.

Don't mind my asking. This is a nice project and all but I would think you could buy a part to just do this. Why are you rolling your own?

This is for temperature control of very sensitive scientific equipment. One or a few pt100 sensors provide feedback for a TEC (Peltier) heater/cooler.

+/- 1 mK (a thousandth of a degree 1 C) over a week would be good. That is 50ppm of the 20C measurement range.

+/- 10 mK over a week might be acceptable. (500ppm of range)

The thermal time-constants will be very long. Finite-element analysis shows 4-5 hours for the "quick" outer part of the instrument and a few days for the thermally isolated innermost parts.

If there are commercial pt100 dataloggers that have readout and stability of below 1 mK that would clearly be an option.

Damn. That is cool...

I have heard of a few things like that. Sadly most of them are not public.

Jim Williams once built a gadget to measure the heat emitted by an amiba. He did it in a thermos. It took multiple control loops.

How much mass does that casing have?

The temperature-controlled part weighs about 20kg I think. Inside that box there are thinner/lighter boxes for passive temperature-stabilization.