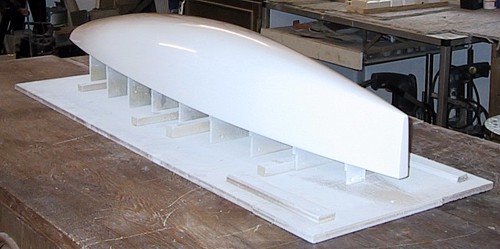

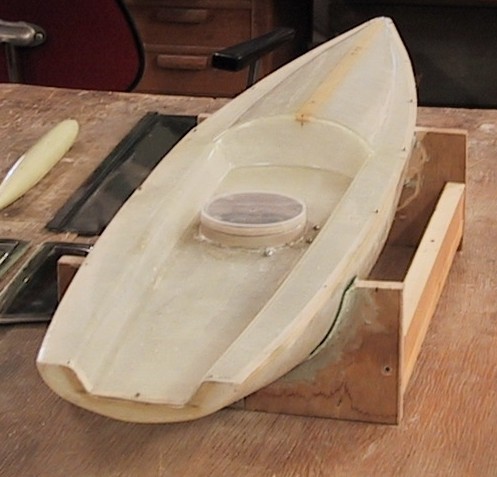

Steinar from Norway wrote to tell me about his Noux project. He started out building a planked wooden Noux (above), but it ended up too heavy, so instead a wooden plug was made (below)

Using this plug Steinar has now made a mould and moulded a few glassfiber Noux hulls. There's no standard deck solution for the Noux yet so Steinar has invented his own, with a central round hatch for access to the electronics.

Anders or Steiner, can you tell me how the Noux sails against the likes of Cockatoos or Azetones? At what angle is the bulb mounted to the keel? I'm planning on building a mold and doing a fiberglass hull. What are the weights and number of layers of glass cloth used.

Thank you in advance for your information and great plan.

Phil

Hi Phil,

If well sailed, built, rigged, and trimmed the Noux will be as competitive as any other design.

"common knowledge" about the best bulb cant angle seems to indicate that the front of the bulb should be angled up about 1-3 degrees. I don't think anyone really knows why, or what the optimum angle is. Lester's site probably has a page on this.

I'm not an exper on moulds, but you want to start out with a hard tooling gelcoat. Two or three layers for a total thickness of maybe 1-2mm. After that you want thinner layers of glass, followed by thicker layers. The bulk of the moulds should be something like 3-5 layers of 300g/m^2 'criss-cross' fibers.

I've been dissapointed by composite moulds a number of times, so my latest thinking is that small components should be made from cnc-cut aluminium moulds, and for the bigger components (hull, deck) we should find a tooling-board that can be easily cnc-cut and used as such as a mould.

For the boat, people usually use 160-165 g/m^2 woven glass cloth, since it's commonly available. Twill weave will have the best drape, i.e. form around curved surfaces easiest. Two layers is sufficient if you reincforce the parts of the hull where higher loads are expected (rudder, keel/mast, jib-attachment). We've also made hulls with three layers throughout and have no trouble building these boats under the minimum weight.

Jari and I are working on an upgrade to our cnc-mill, so moulds for fin, rudder, bulb might be available at some point. We haven't found an economic way to do the hull mould yet. A cnc-cut hull plug in MDF would be doable, but a lot of work.

Let me know how it goes,

Anders

Is the Noux available as a kit, I am looking for an IOM .

what would the cost and delivery time be to the UK.

regards Andy

At this time no kits are available.

I could probably make cnc-milled moulds for the fin, rudder, and bulb available later this year. Hull moulds are more difficult due to their large size.

Anders

Some more interesting wooden Noux building pictures here:

http://www.rcsailing.hu/photos/wooden_noux_building_(builder_forster_tamas)/