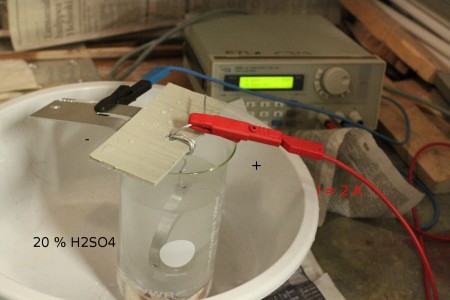

We thought all those aluminium bits the cnc-mill spits out needed to look all nice and pretty. So a test with some DIY-anodizing today. Following one of the many guides out on the interwebs (here and here) we mixed ourselves some 20 % sulphuric acid, inserted an aluminium plate which works as the cathode, and suspended the part to be anodized from an aluminum wire.

This was tested on these rings which hold the finder-scope on my telescope.

After about 30 min of anodizing with the current around 2 A the part was rinsed in water and then put into hot water containing black color used for coloring clothes. The part was then boiled in this solution for another 20 min. The guides tell me the oxide layer formed in anodizing is first very porous and will absorb the color, and while boiling the pores close leaving a less brittle oxide-layer and sealing the color within.

This wasn't too scary and the initial results look promising. More to follow later probably...

pretty colours in excess over here!

http://www.focuser.com/atm/anodize/anodize.html

here's another DIY anodizing report

http://forum.fi-bmx.com/viewtopic.php?f=2&t=5809

I've recently started anodizing at home after first trying it 15 years ago. Here's my current project: http://www.homemodelenginemachinist.com/index.php?topic=5189.msg61049#msg61049